Once a surplus product looking for uses, soybean oil has become a sought-after renewable fuel feedstock. As demand for green energy options grows across the globe, production of lower-carbon fuels — specifically renewable diesel — is poised to skyrocket.

Renewable diesel production capacity nearly doubled, from 971 million gallons per year in May 2021 to 1.92 billion gallons in May 2022, according to the U.S. Energy Information Administration. Over that same period, there was little additional soybean oil supply available, so prices moved to historically high levels, says Todd Biedenfeld, director of vegetable oil and sunflower sales for CHS.

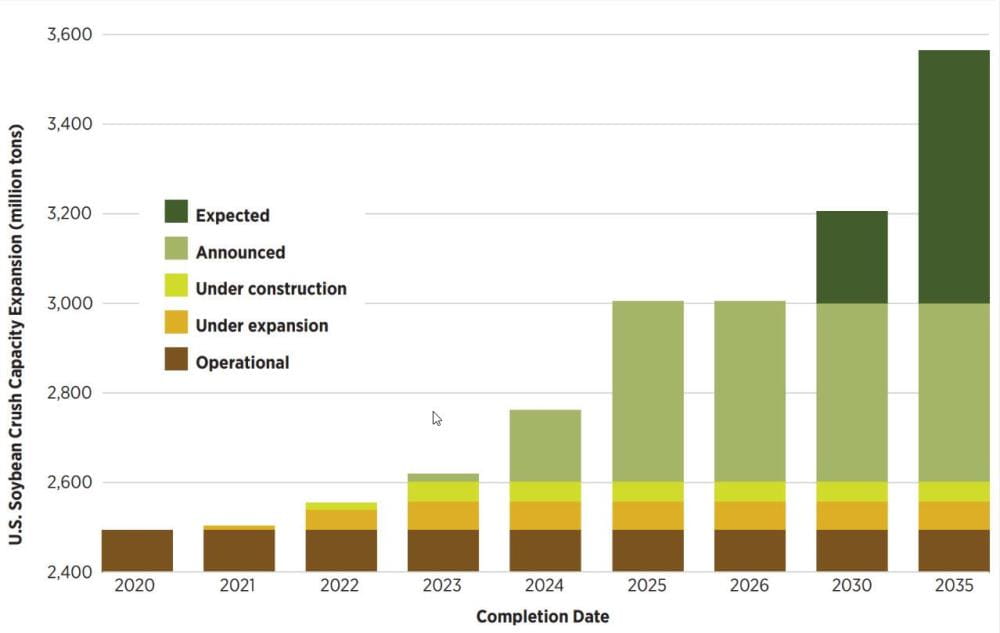

Today, nearly a dozen new soybean processing plants or plant expansions are underway in the Midwest alone and even more new facilities are on the drawing board, he notes. “The soy crush market is trying to recalibrate itself, but we’re still seeing high values for both futures and basis. That’s contributing to healthy margins, which are being reinvested into industry expansion.”

Meeting soybean oil demand

In time for the 2021 harvest season, CHS completed a $100 million renovation of its Fairmont, Minn., soybean processing plant that produces crude soybean oil to expand annual crush capacity by 30%. Built in 2003, the plant operates around the clock, receiving 350 truckloads a day on average and drawing soybeans from growers and cooperatives within a 90-mile radius of the plant, says Jim Graham, director of capital projects for CHS global grain and processing businesses.

Expansion is also underway at the CHS soybean refinery in Mankato, Minn. The plant is already one of the largest vegetable oil refineries in the U.S. “When all upgrades are completed later this year, annual refined soybean oil production at the Mankato facility will increase by more than 35%,” Graham says. “Our Mankato facility produces refined, bleached and deodorized soy oil for food-grade use, and our flour mill produces soy flour that is sold around the world.

“We’ve been able to orchestrate this construction and renovation without interrupting the day-to-day operations of either the crush plant or the refinery,” he says. All soy oil produced at the Fairmont plant is trucked about 60 miles to the Mankato facility for refining, Graham explains, making coordination of the two projects critical.

“With these expansions, CHS is well-positioned to meet the growing demand for soy oil,” says Darrin Carlson, director of oilseed crush at CHS. “CHS has been in the soy crush business for decades and we’re in it for the long haul. It has allowed us to capture the increase in margins that we’ve seen in recent years, and it also puts us in a good position to explore other opportunities for growth in the future.”

Adding value for owners

Soybean producer Richard Stadheim has sold much of his crop to the Fairmont plant since it opened in 2004. “I was really pleased when CHS built this facility in southern Minnesota, close to growers. We’ve always hauled our beans there directly because it means more dollars in our pocket.”

Along with his two sons, Bennett and Garrett, Stadheim raises corn, soybeans and beef cattle near Albert Lea, Minn. He says he appreciates the recent Fairmont facility upgrades.

“Unloading is even easier now and we’re usually in and out of there in less than 30 minutes. It’s a really nice facility, very clean and efficient, and the employees are very good to work with. CHS should really be proud of that plant.”

Defining renewable fuels

A green tsunami is sweeping the globe and most corporations want to show they’re involved, says Joe Lardy, CHS research analyst. “We’re seeing environmental, social and governance [ESG] initiatives to reduce the carbon footprint of businesses, their processes and end products. Renewable fuels are a big part of that effort.”

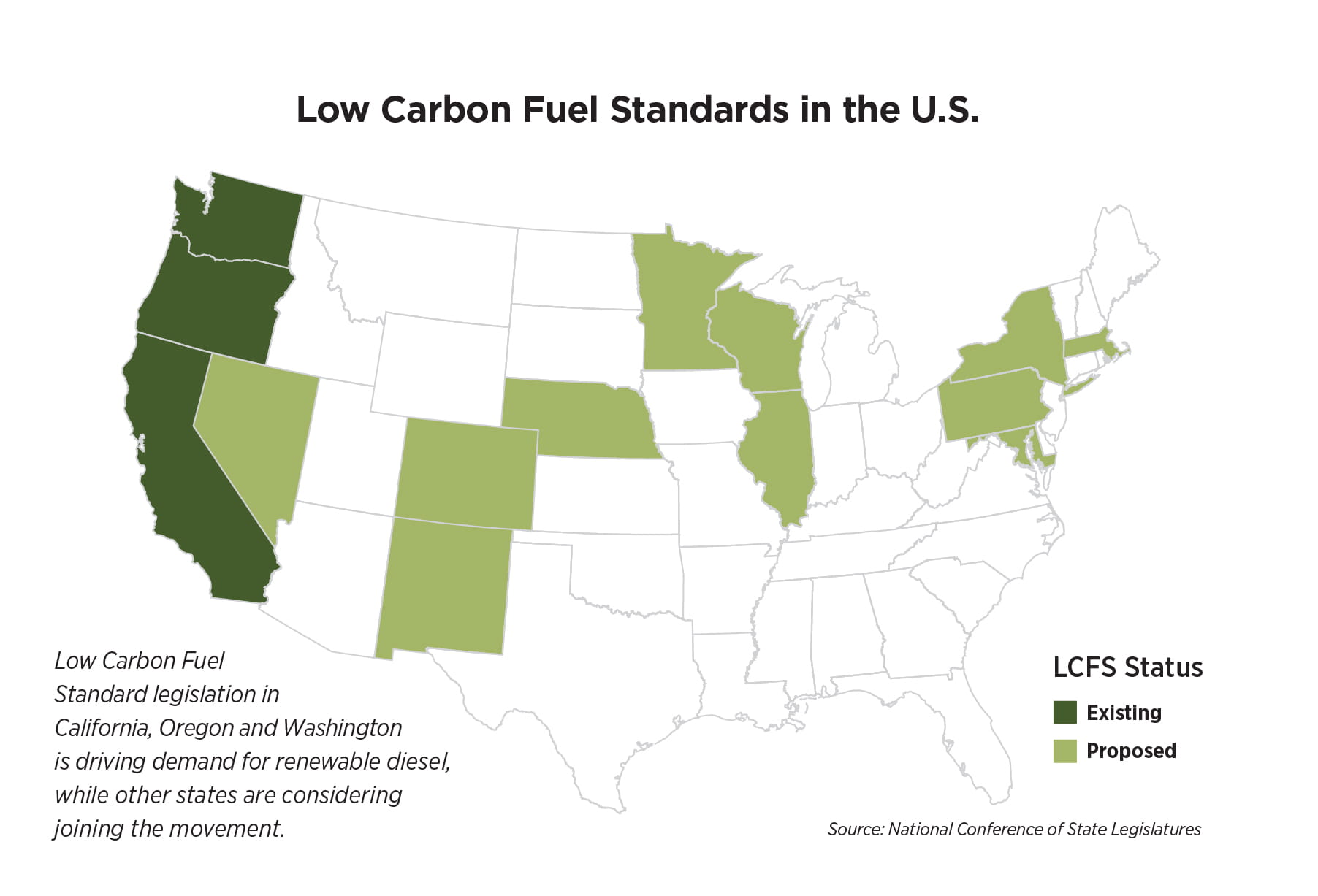

A Low Carbon Fuel Standard (LCFS) has been enacted in three states — California, Oregon and Washington — and other states are considering similar legislation and standards. In 2022, the U.S. renewable diesel market was between 1.5 billion and 1.6 billion gallons, says Ron Batey, refined fuels pricing and economics director with CHS. “Forecasts say that by 2026, there will be an additional 1.1 billion gallons of renewable diesel demand generated from LCFS legislation enacted in those three states alone.

“Currently, 80% to 85% of all U.S.-produced renewable diesel is being used in California,” he says. “As of last summer, California had already replaced 45% of petroleum diesel used with biomass-based diesel. Washington began implementing similar LCFS legislation at the beginning of this year, with demand for renewable diesel there expected to increase quickly.”

Airlines are also looking for sustainable fuel, notes Lardy, and renewable diesel would be a logical feedstock. “When you start to add up the potential demand, even just within the United States, it’s huge.”

To be considered renewable, a fuel must be produced from non-fossil feedstock, such as plants, animal fats or processing waste or byproducts. Ethanol led the way in biofuels, but that industry may have topped out, says Lardy.

“There’s a 10% blend wall for ethanol and a limit to how much more can be used,” he says, “so the energy industry has been looking at alternative feedstocks, such as soy oil, used cooking oil and even beef tallow. Soybean oil offers the greatest potential for producing renewable biodiesel because it’s already a major commodity and it’s scalable —we can make more.”

Renewable diesel burns cleaner than traditional biodiesel, which is a blend of renewable fuels and petroleum-based diesel. Renewable diesel is made only from renewables, so it’s more efficient and generates lower emissions, adds Biedenfeld. “From a use standpoint, there is no difference between renewable diesel and petroleum-based #2 diesel, so it’s considered a drop-in product. That makes it a very attractive fuel option for meeting low-carbon mandates in some states.”

What’s fueling policies?

Three key drivers have supported the development of renewable fuel policy incentives in the United States, according to Dan Mauer, CHS government affairs Washington, D.C., representative.

1) Environmental benefits

Renewable Fuel Standard regulations are administered by the U.S. Environmental Protection Agency (EPA) and mandate that a portion of U.S. motor fuel must be blended with renewable fuels to reduce greenhouse gas emissions.

2) Economic development

The federal biodiesel tax credit was established in 2004 to allow biodiesel to be more competitive with petroleum-based fuels.

3) Energy security

The Low Carbon Fuel Standard (LCFS), set at the state level, is focused on reducing the carbon index. California was the first to adopt this standard in 2009, and that standard is emerging as the favored approach in other states.

“The Inflation Reduction Act of 2022 extends current tax credits for renewable diesel through 2024 and creates a clean fuel production tax credit starting in 2025 that will simplify alternative fuel qualifications based on lifecycle carbon reduction — the larger the reduction, the bigger the tax credit,” explains Mauer.

There is a degree of uncertainty about all renewable fuel policies because they are dependent on the political will of both federal and state legislatures, he notes, “but there is a lot of enthusiasm for renewable diesel as a sustainable fuel to help states meet LCFS goals. Soybean oil is going to be a critical feedstock in accomplishing that.”

Soybean meal conundrum

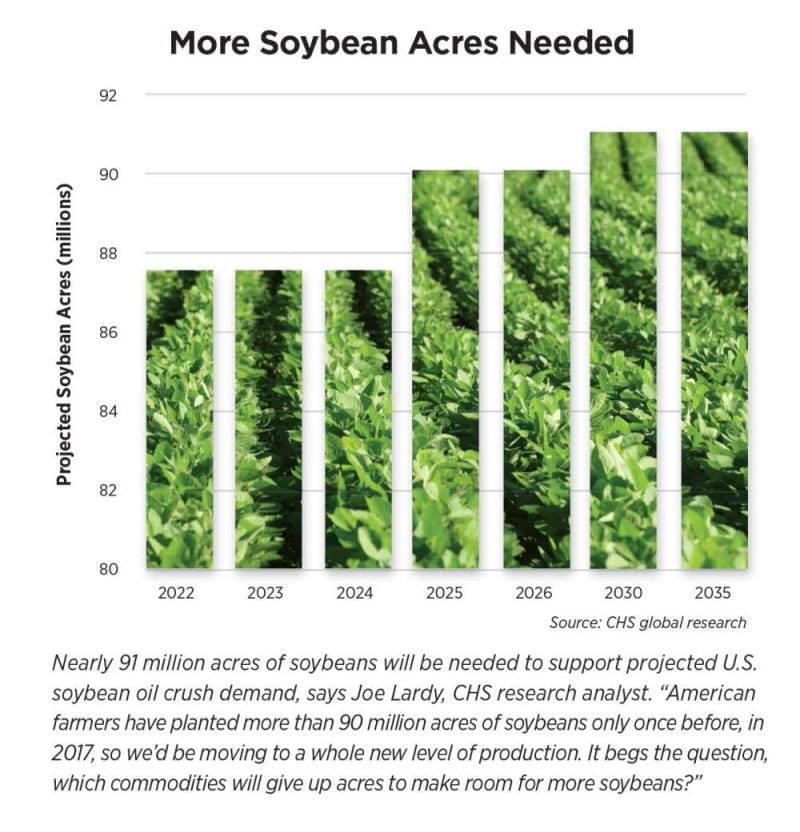

Historically, U.S. soybeans have been crushed primarily for soybean meal, which comprises 80% of the intact bean. With projected sharp increases in soy crush volumes over the next decade, where will all the meal go?

Currently, about two-thirds of soybean meal produced in the U.S. is fed to U.S. livestock and about one-third is exported, says Carlson. With the projected increase in soybean crush to meet renewable diesel demand, more meal will likely be fed to U.S. livestock.

“Soybean meal is established globally as a premium protein source for feed. If it becomes more price-competitive, it could displace some DDGS [distillers dried grains with solubles] from ethanol production,” says Carlson, “but the United States will also need to increase soybean meal exports and look for new markets.

“It doesn’t matter how high soybean oil prices get. Processors need to have a consistent market for soybean meal,” he adds. “Most plants have only a few days’ worth of meal storage on site. Railroads and trucks have to be moving that meal all the time in any weather. That will require additional investments in infrastructure throughout the country.”

Handling all that additional meal will also require expanding export facilities at major ports around the country, he adds. To help meet the need, CHS is expanding its Myrtle Grove, La., export terminal. The $105 million investment will include storage and handling upgrades, which will grow market access for farmer-owners and help move 30% more bushels and byproducts like soybean meal through the facility. Expected to be completed in late 2023, the construction project will bring total storage capacity to 850,000 bushels.

To further expand export capabilities, CHS recently announced intent to expand its TEMCO, LLC, joint venture operated with Cargill to include a terminal in Houston, Texas. Located 40 miles inland from the Gulf of Mexico via Galveston Bay, the added facility will provide shipping access for grains, oilseeds and byproducts through the Port of Houston.

Beyond beans

“The tide has risen for other oil crops thanks to the increased demand for soy oil,” says Biedenfeld. In late 2022, the EPA approved canola oil as a renewable feedstock after diesel made with canola was shown to reduce emissions by 50% compared with standard diesel fuel. CHS owns and operates a canola processing and refining plant located in northern Minnesota, outside Hallock. Acquired in 2015, the plant processes 400,000 tons of canola seed annually.

“The margins are still higher selling canola oil into the food market, but we have started to sell some canola oil for renewable diesel as those prices have become more competitive,” says Biedenfeld.

“As a company, CHS has a long history of supporting food processing sectors, and that’s not likely to change,” he adds. “Decades of experience in the oil seed industry, along with our recent expansions, make CHS well-equipped to help meet the needs of a growing renewable diesel market as well.”